Designing for the safety, security, and high precision of heavy ion therapy

Scroll Down

There are currently seven heavy ion therapy facilities in Japan, five of which were designed by Nikken Sekkei. Utilizing our technical expertise and knowledge cultivated through our extensive experience, we are contributing to the provision of patient hospitality as well as the safety and precision of this advanced treatment. Here, we introduce the Osaka Heavy Ion Therapy Center as our representative example.

CATEGORY

Japan’s world-class, cutting-edge cancer care

Heavy ion therapy is an advanced medical treatment originating in Japan since it was the first in the world to succeed in actual operation. Although treatment costs are high, insurance coverage was expanded in 2022, enabling this treatment to become available to a larger population. As a form of cancer treatment that is gentle to the human body (no resection, fewer side effects, and no hospitalization), it is attracting attention from around the world.

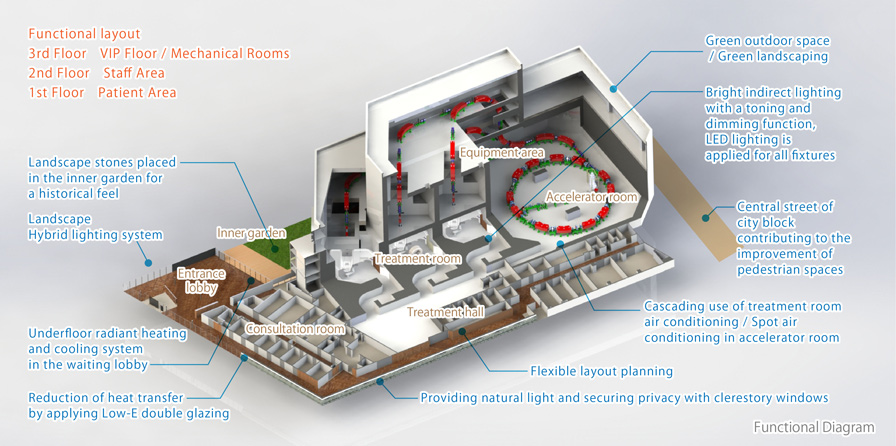

A “patient-first” space

Entrance Lobby

Entrance Lobby

Treatment hall entrance on the first floor

Treatment hall entrance on the first floor

-

Treatment Hall

Treatment Hall

-

Treatment room

Treatment room

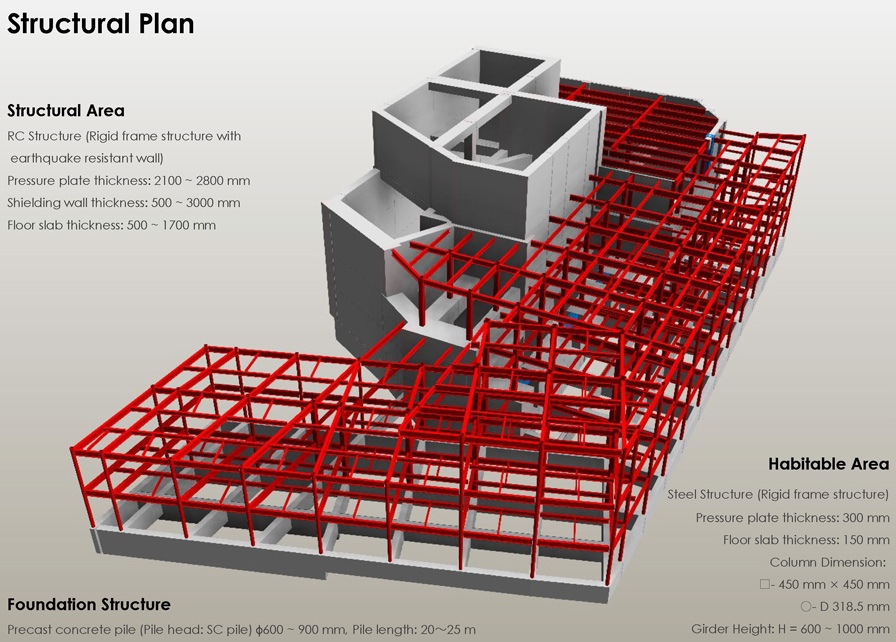

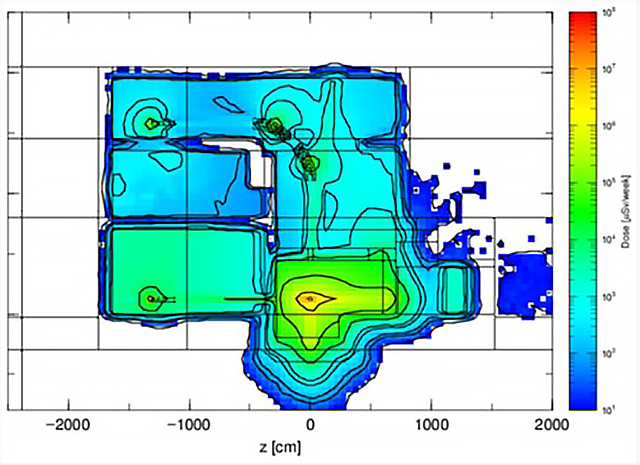

Original radiation shielding technology provides safety and economic efficiency

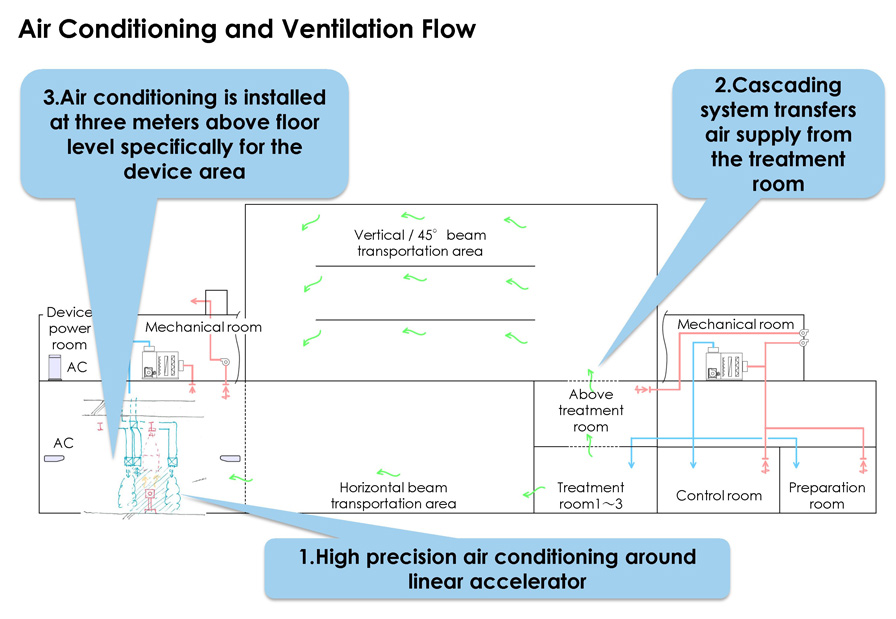

Precise temperature control realizes high treatment accuracy

Accelerator room interior

Accelerator room interior

Promoting heavy ion therapy facilities to the world

Heavy ion therapy facilities require advanced safety measures and backup measures for treatment devices. Nikken Sekkei is an architectural design firm that has been involved in much of the world’s heavy ion therapy facility design and has accumulated highly specialized expertise. Based on our experience, we hope to contribute to spreading heavy ion therapy both domestically and abroad.

Photo:PhotoCommunication inc