LCD/Cx[Commissioning]

Scroll Down

Performance validation is the key when considering Life Cycle Design

When thinking about the Life Cycle Design (LCD) of buildings, it is vitally important to consider how to build in ideas and techniques that will allow the building to be used for a longer period. Cx (commissioning, which is performance validation) is one technique for maintaining building performance in the long term. Continuous commissioning is particularly important at the operation stage, to keep energy consumption at the minimum level at all times. Nikken Sekkei Group makes diverse proposals to support continuous commissioning.

CATEGORY

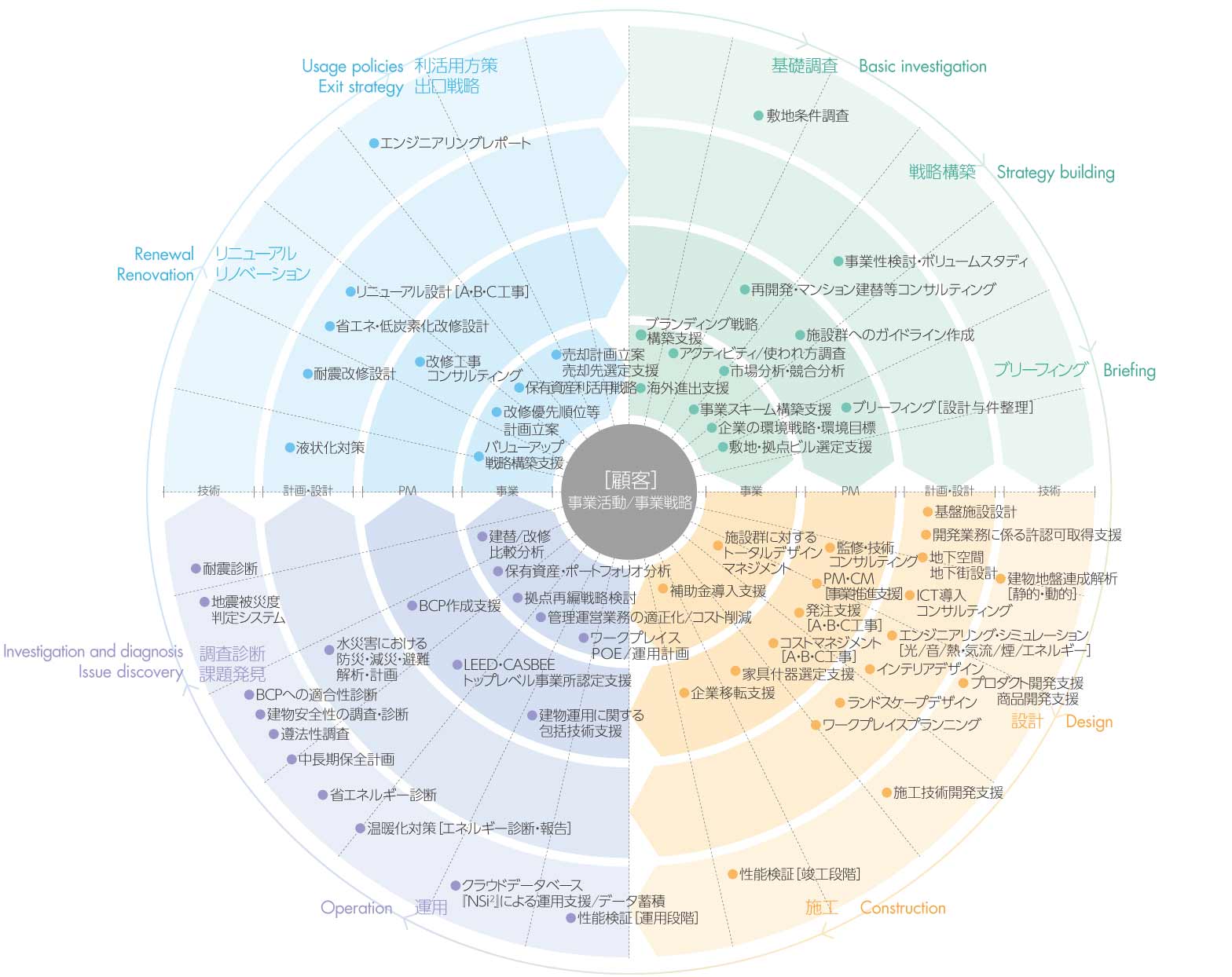

Life Cycle Design Provided by the Nikken Group

We propose services for each category; business, project management (PM), planning and design, and technology throughout the life cycle, starting from basic investigation at the project conceptualization stage, through strategy building, briefing, design, construction, operation, investigation and diagnosis, issue discovery, renewal and renovation, usage policies, to exit strategy.

Commissioning (Performance Validation)

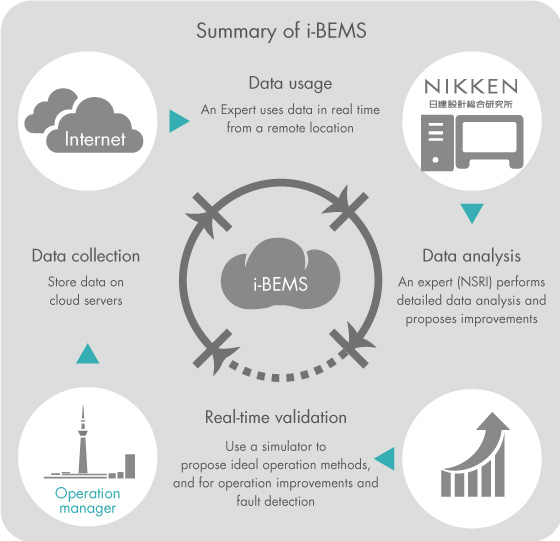

Intelligent-BEMS

Intelligent-BEMS

Intelligent-BEMS (i-BEMS) gathers data of the target building’s energy consumption and the operating status of its equipment via the Internet and resides it on a high-security external server. This system enables experts to analyze stored data in real time. The simulator (using the LCEM tool) within i-BEMS is used to build a model corresponding to the services systems within the customer’s building, input measured data, calculate the current ideal operation method with high precision, and propose more efficient operation methods

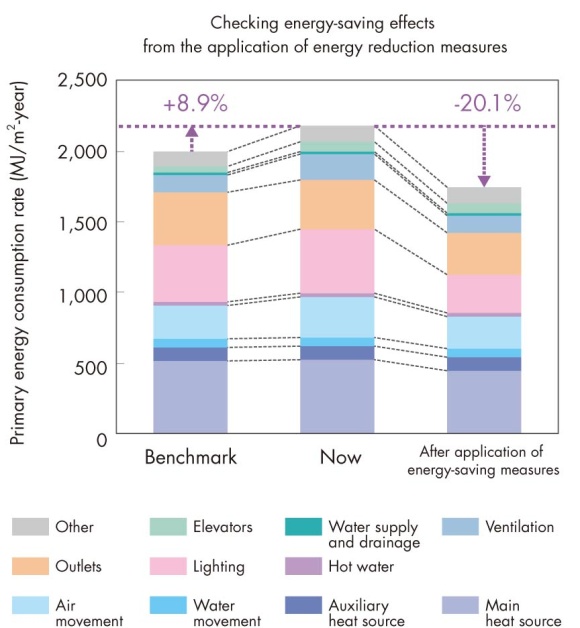

Energy-saving and Carbon-reduction Refurbishment Design

Example of calculating effects from the application of energy-saving measures

Example of calculating effects from the application of energy-saving measures

From the results of the energy analysis, we address points capable of energy-saving refurbishment or improvement by selecting energy-saving methods based on comprehensive consideration of the purpose of the facilities, how they are actually used, the numerical targets set by legal regulations, and other aspects. As a result, we can study investment efficacy by making trial calculations of refurbishment, operation, and other costs. After renovation, we validate the expected effects at the design stage have been realized.

Eco Monitors to Motivate More Ecological Operation

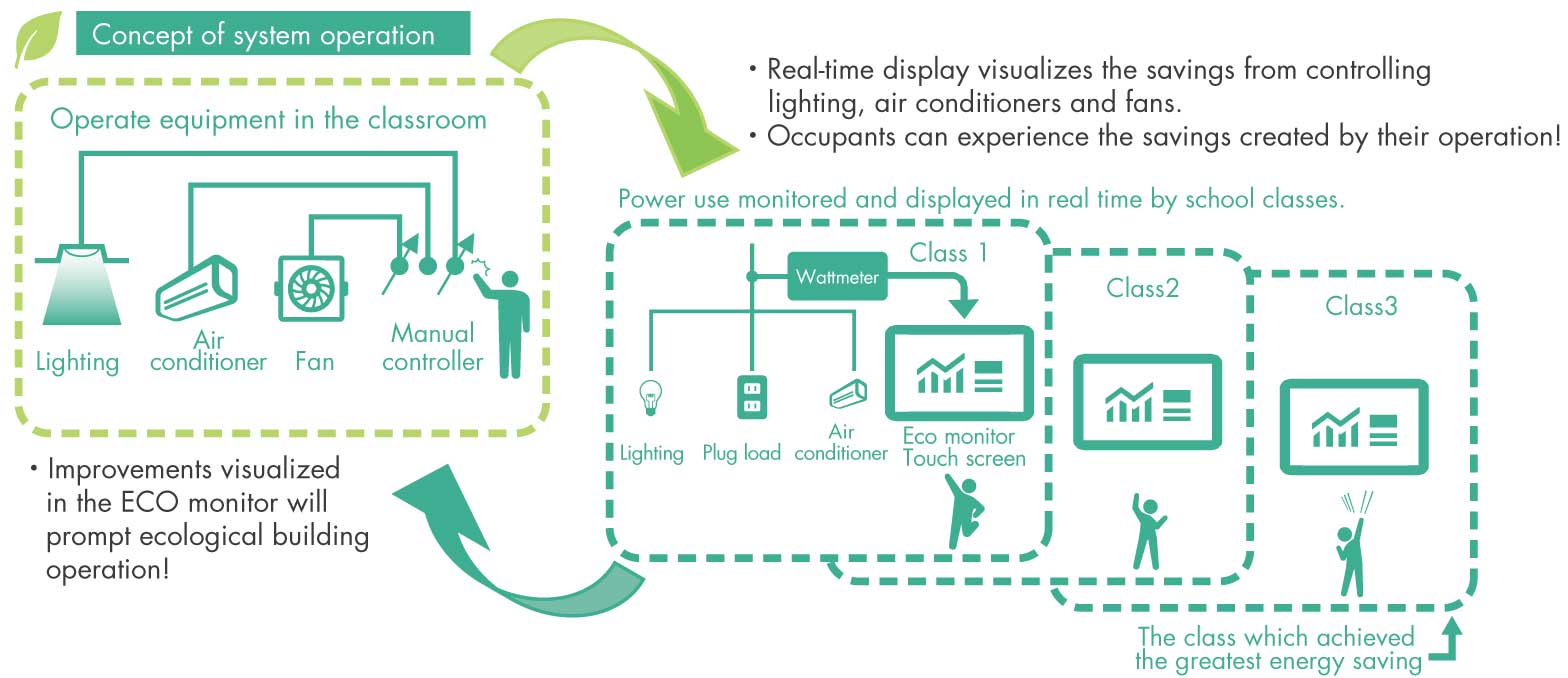

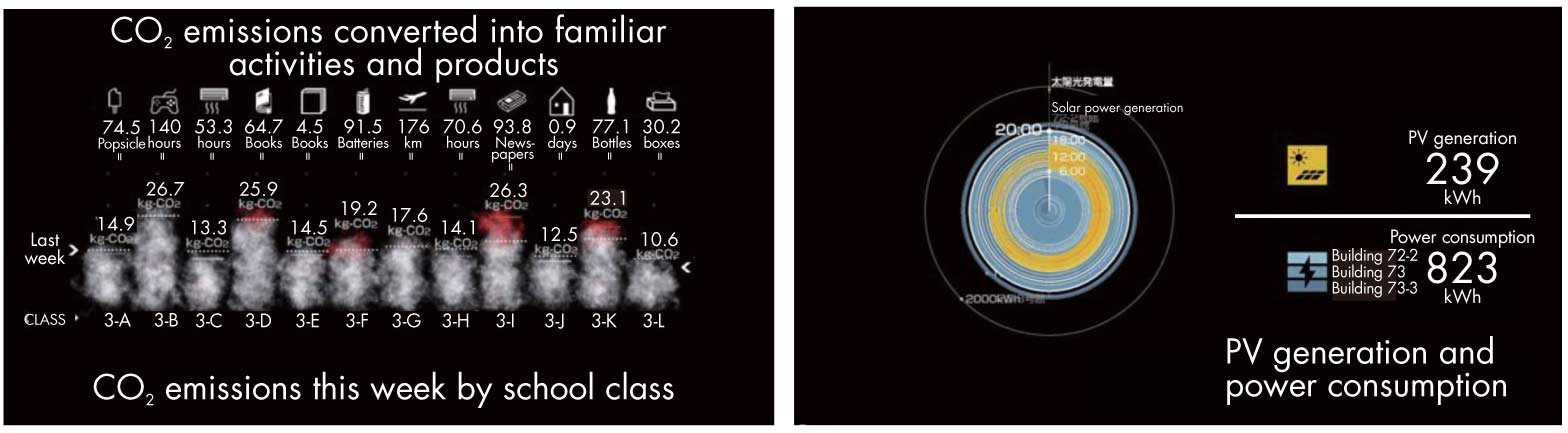

The concept of real-time eco monitoring

The concept of real-time eco monitoring

Example of real-time eco monitoring

Example of real-time eco monitoring

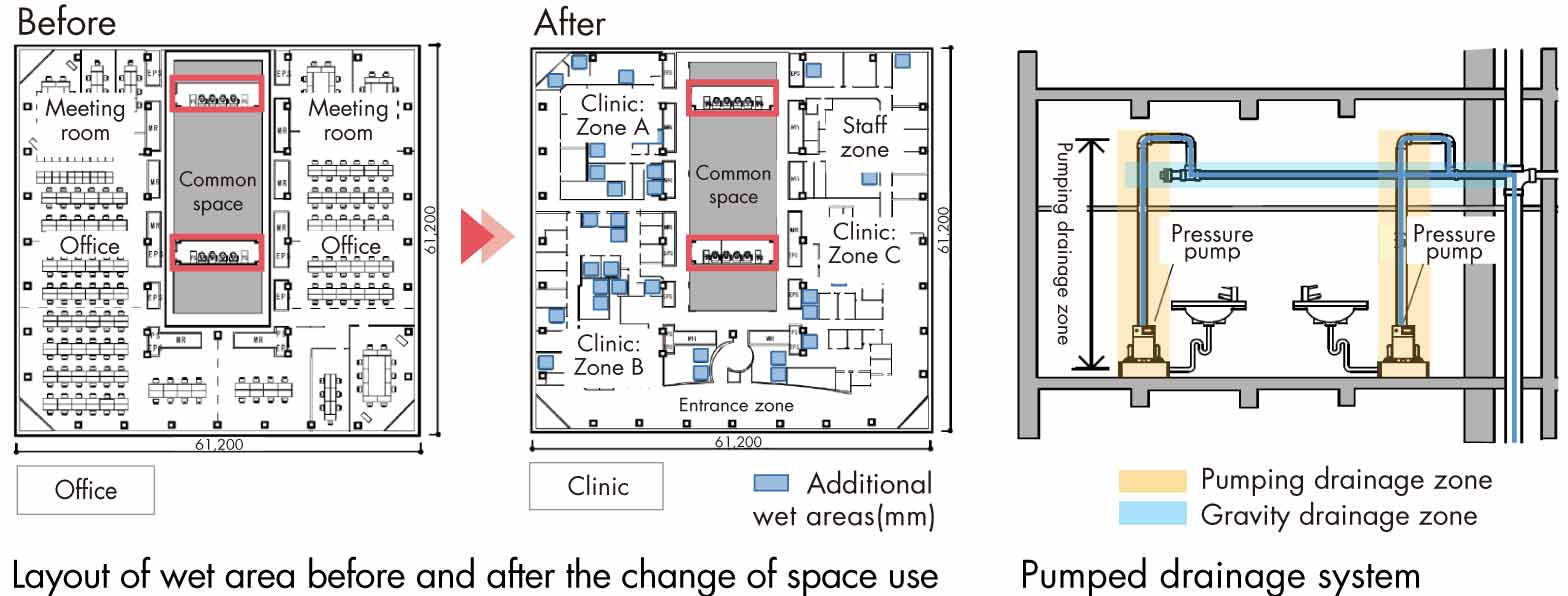

Flexible Plumbing Design

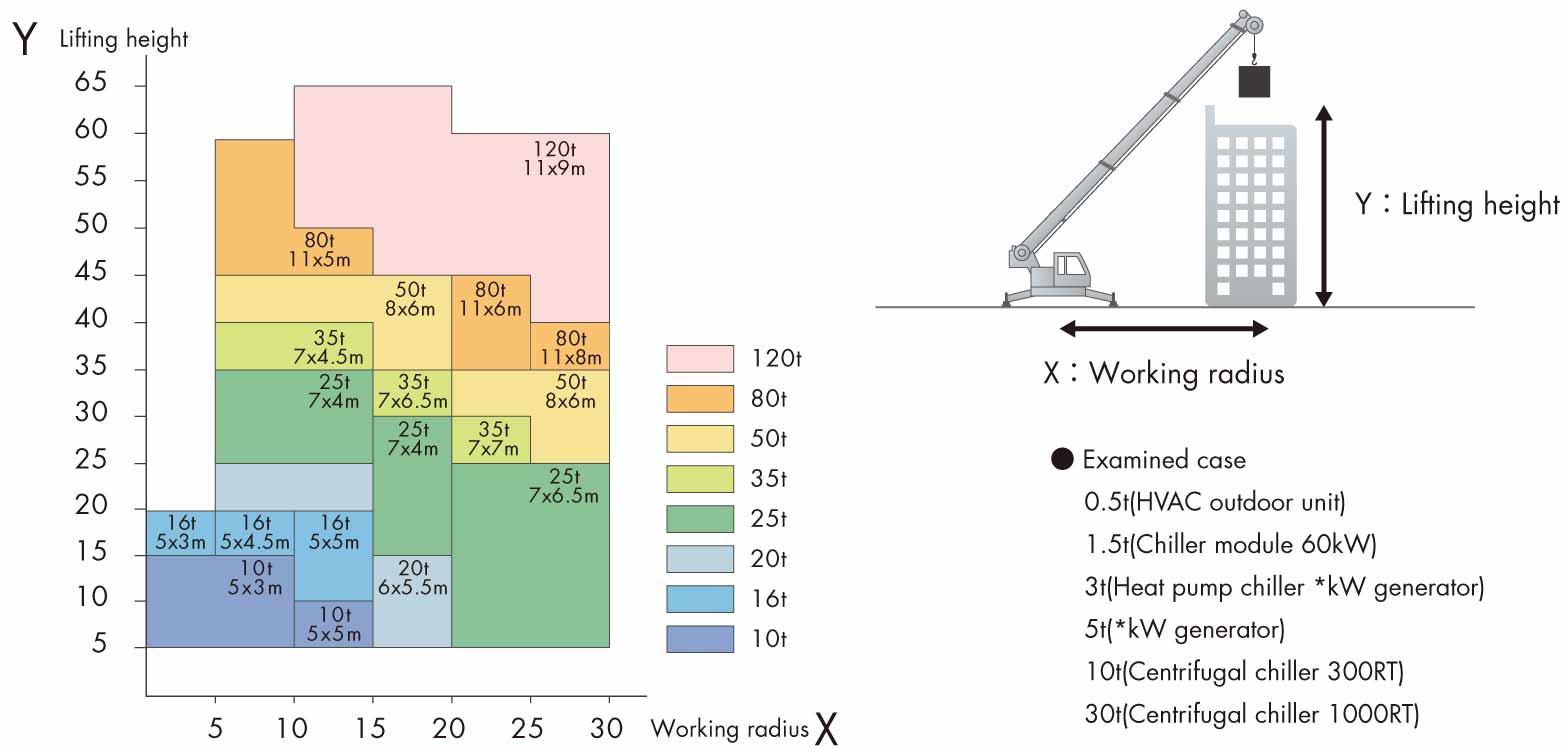

Considering Equipment Renewal and Transportation Plan from the Initial Planning Stage

Simple chart for lift planning

Simple chart for lift planning

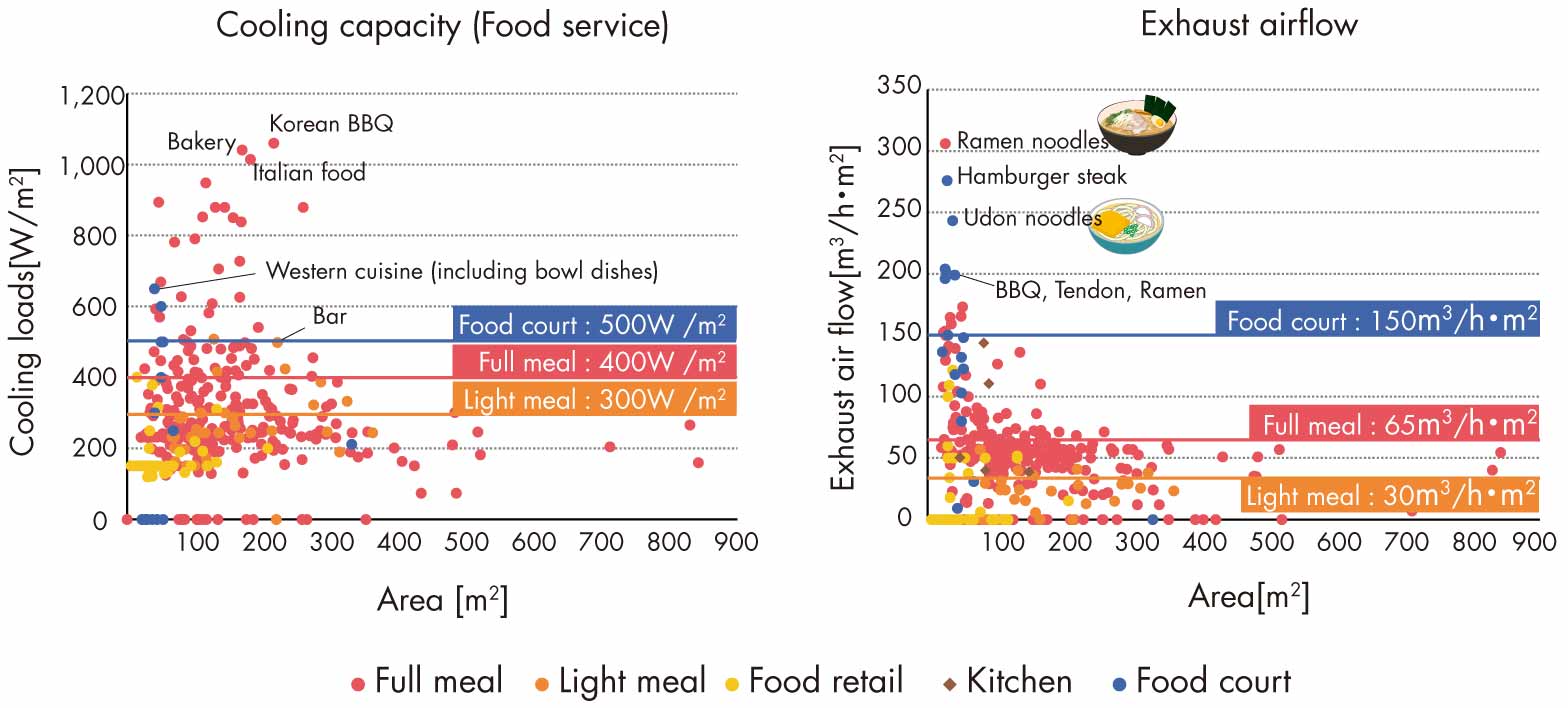

Accurate Equipment Design Based on Statistical Data

Statistics of cooling loads and exhaust air volume for food service facilities

Statistics of cooling loads and exhaust air volume for food service facilities

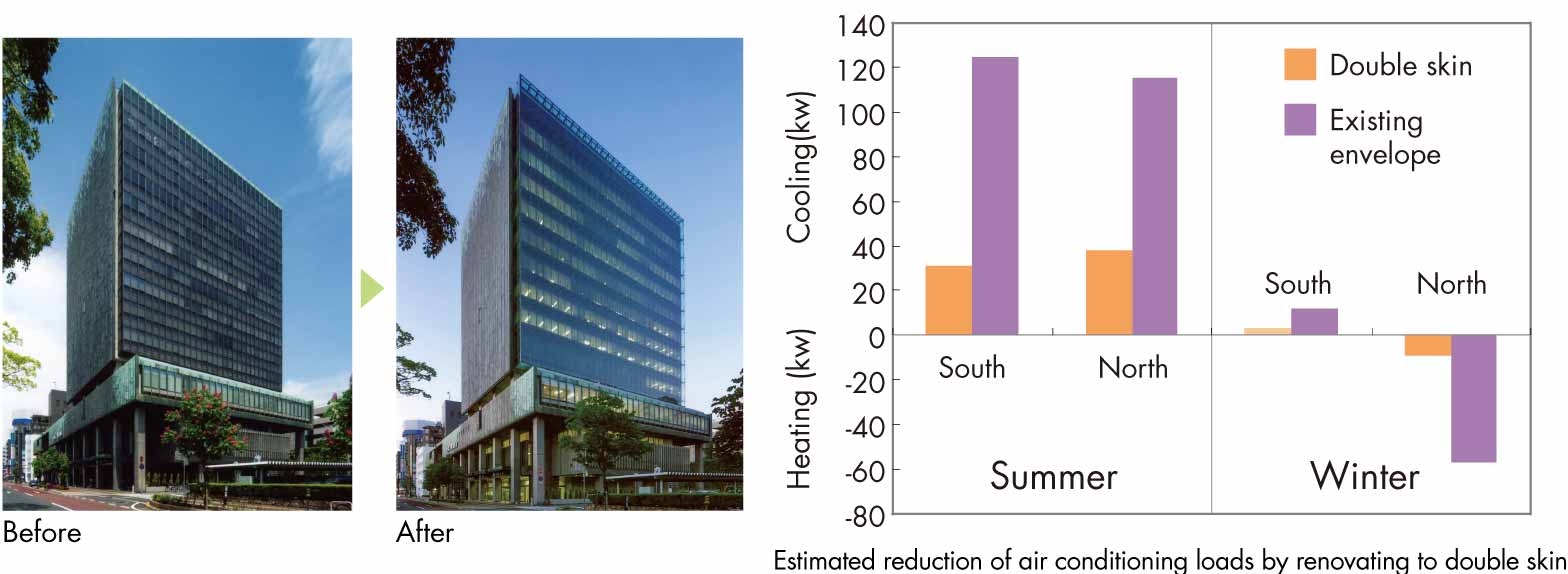

Environmental Performance by Envelope Renovation