On May 15th, Nikken Sekkei announced the prototype of a next-generation skyscraper incorporating various ideas to reduce CO2 emitted over the building life cycle, i.e., whole life carbon. Reductions up to 40% can be achieved by designing for diverse work styles, future conversions, and high environmental performance. We aim to implement the elements of this prototype in real-world projects through co-creation with our clients.

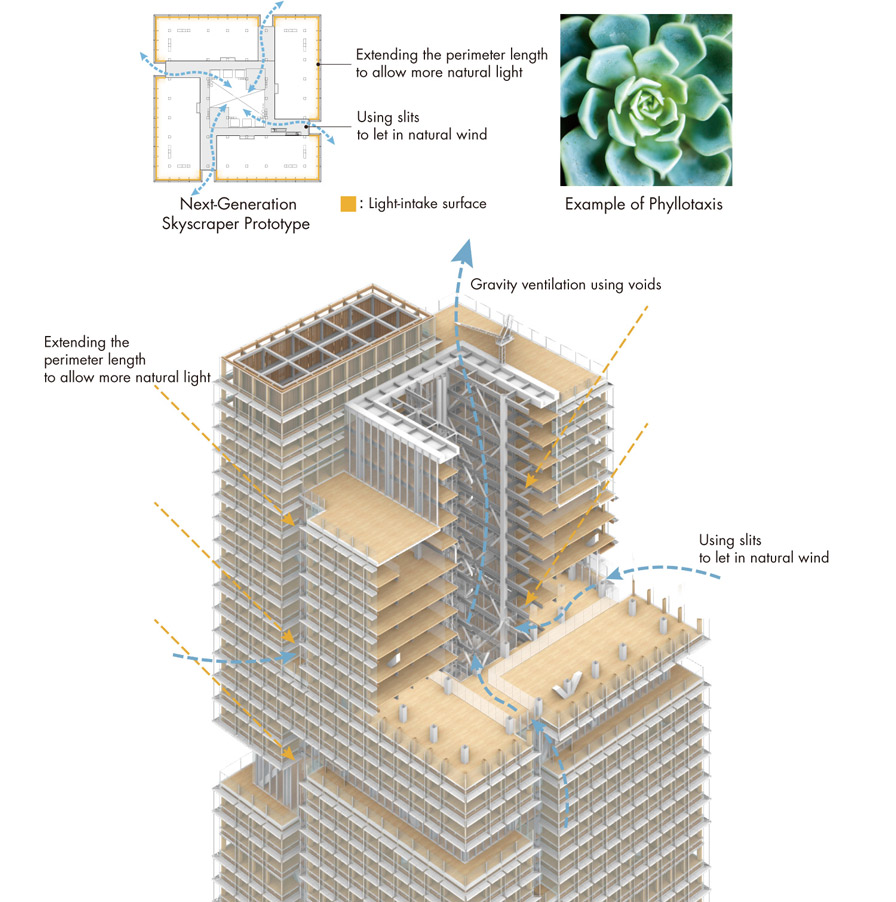

Figure 1. Overall image of the next-generation skyscraper prototype

Figure 1. Overall image of the next-generation skyscraper prototype

Aiming for a new standard in skyscrapers promoting decarbonization and diverse work styles

2023 was the hottest year on record*1, and the average temperature is expected to rise by 1.5 degrees by the early 2030s*2, highlighting the need for global efforts to significantly reduce greenhouse gases. Under Japan’s “2050 Carbon Neutral Declaration,” the government has been tightening regulations, such as raising energy efficiency standards for large non-residential buildings in April 2024. The industry is currently focused on CO2 emissions associated with building operation, i.e., operational carbon, but the importance of reducing CO2 emitted during the construction, refurbishment, and demolition phases, i.e., embodied carbon, is garnering attention worldwide as a means to lower whole life carbon emissions. Some countries have already enacted regulations in this regard.

Furthermore, there is a growing need for offices that offer employees the freedom to choose the location and environment of their workspaces, encourage communication with others, and promote wellness by connecting with nature, as well as flexible plans that allow for future refurbishments and changes in building use. Nikken Sekkei has developed a prototype that addresses these changing values and decarbonization, aiming to create a versatile model that sets a new standard for skyscrapers.

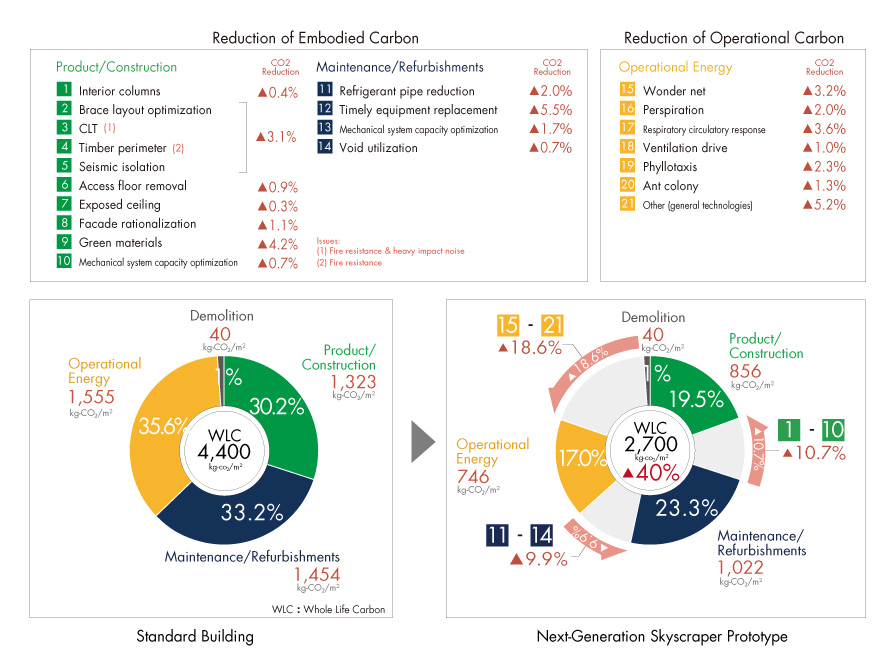

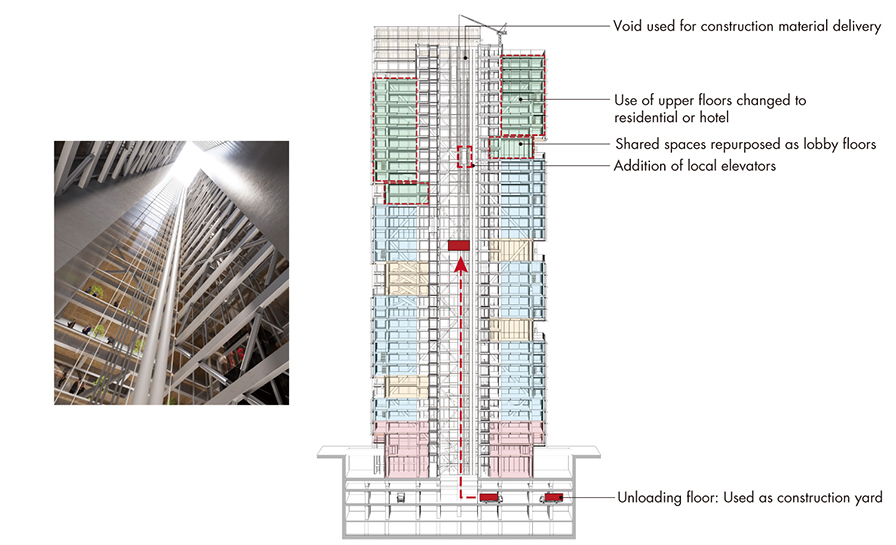

Reducing CO2 up to 40% over the building life cycle through the rationalization of structural and mechanical design

To minimize the CO2 footprint of this new prototype, we reconsidered various common practices for large-scale offices, identified the truly essential functions, and thoroughly rationalized its structural and mechanical design. Specifically, the following elements contribute to decarbonization, reducing whole life carbon up to 40% over the building’s lifespan.

Figure 2. Overview of whole life carbon reduction measures used in the next-generation skyscraper prototype

Figure 2. Overview of whole life carbon reduction measures used in the next-generation skyscraper prototype

*1 Based on the March 2024 State of Global Climate report by the World Meteorological Organization (WMO).

*2 Based on the March 2023 report by the United Nations Intergovernmental Panel on Climate Change (IPCC).

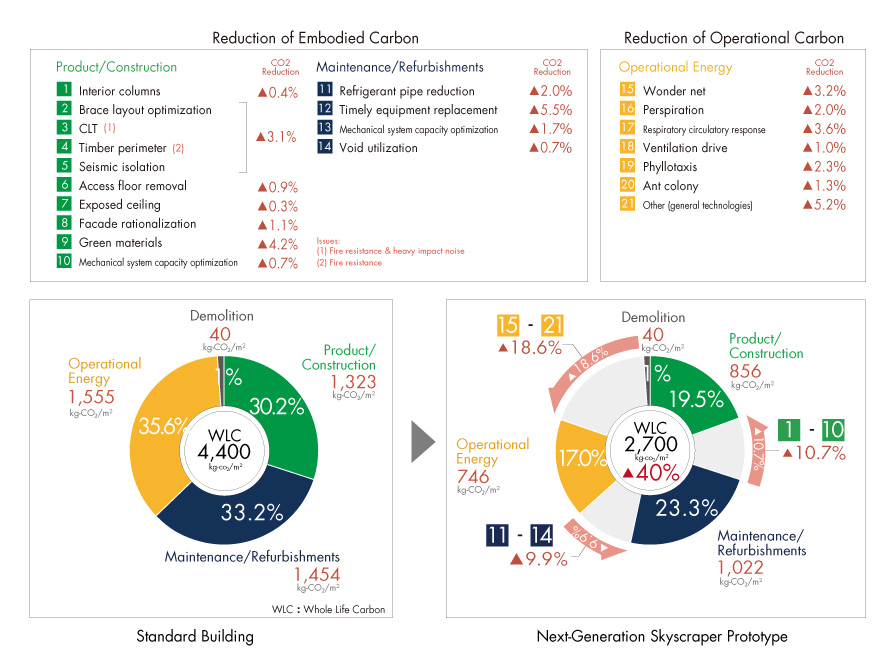

1. Rationalization of structural design

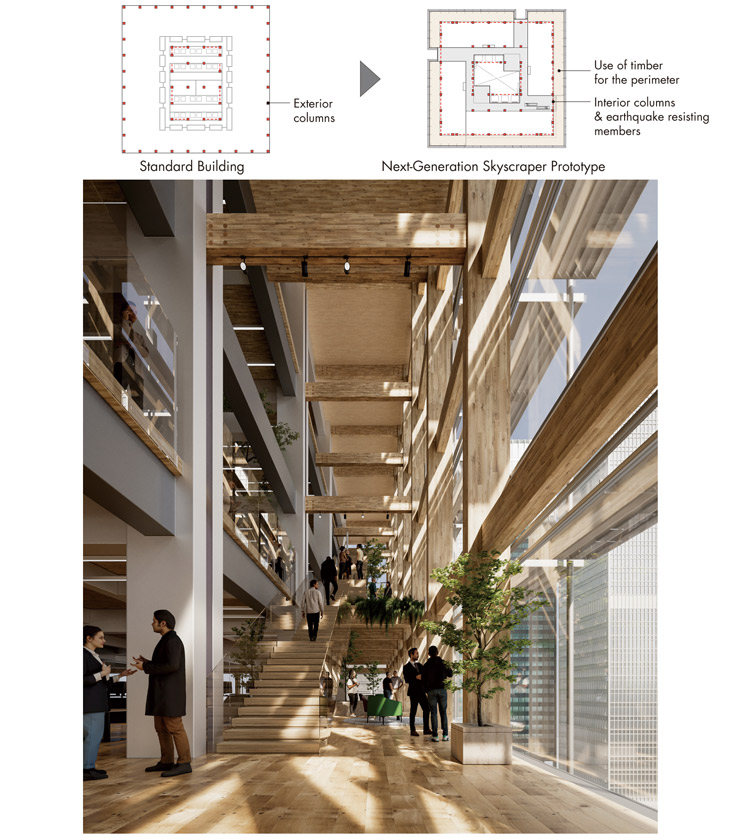

Optimizing the frame structure and using timber for the perimeter

Conventional offices with wide, column-free spaces require large amounts of steel due to long-span structures and the concentration of earthquake resisting members around the core. In this prototype, columns and other elements are placed in structurally rational positions and the perimeter is made of wood. This reduces the use of steel, better accommodates changes in building use, and significantly cuts CO2 emissions during construction.

Figure 3. Timber perimeter

Figure 3. Timber perimeter

Surrounded by wood, the texture-rich window areas create a new workplace that enjoys natural light and wind.

2. Rationalization of mechanical design

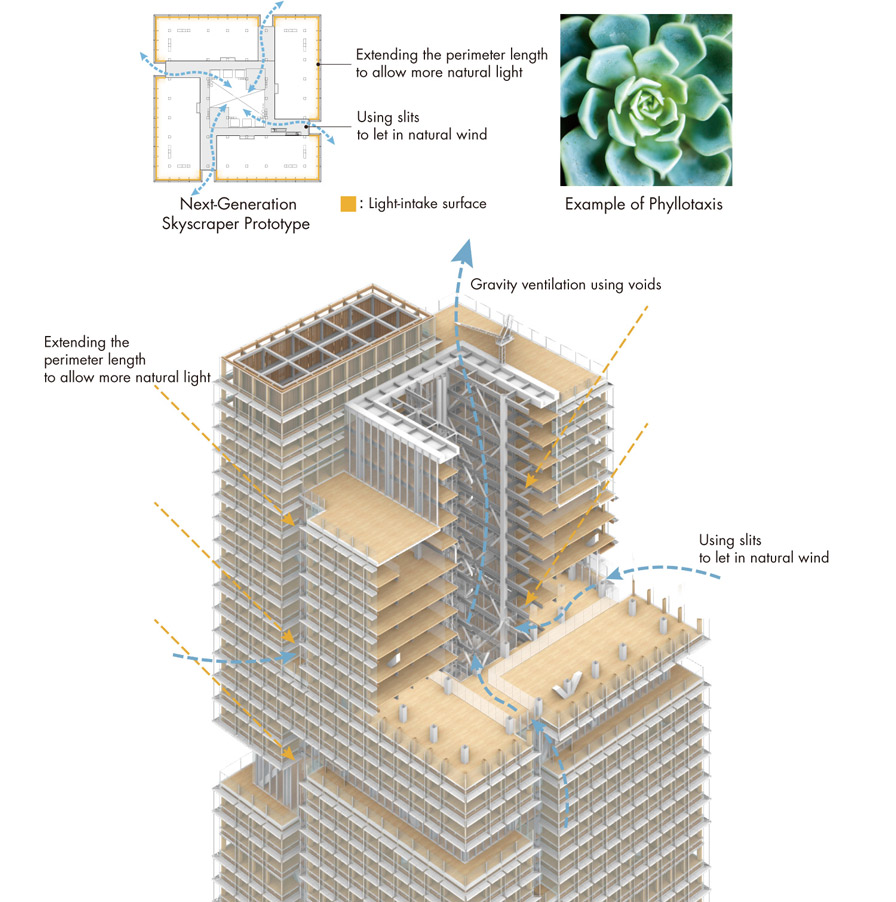

Applying biomimicry for high environmental performance

As an approach to mechanical design, we have applied biomimicry*3, drawing inspiration from the mechanisms of living organisms. One example is a heat recovery system mimicking the “wonder net” mechanism, where interwoven arteries and veins exchange heat to prevent drops in body temperature. Another is a “high sensible heat operation” and water spray system for air conditioners, similar to the process of perspiration for body temperature regulation. With these energy efficiency measures a BEI value of 0.23*4 was achieved. Furthermore, inspired by the arrangement of leaves on a plant stem (phyllotaxis), slits on all sides and a central void were created to allow light and air to permeate the space.

Figure 4. Environmental planning inspired by phyllotaxis

Figure 4. Environmental planning inspired by phyllotaxis

*3 Design that learns and mimics shapes, processes, and ecosystems found in nature.

*4 Abbreviation for Building Energy Index. Calculated as the ratio of primary energy consumption of the designed building to the reference building, it is an indicator of the building’s energy efficiency. A BEI value of 0.8 or less complies with current standards, with lower values indicating higher energy performance.

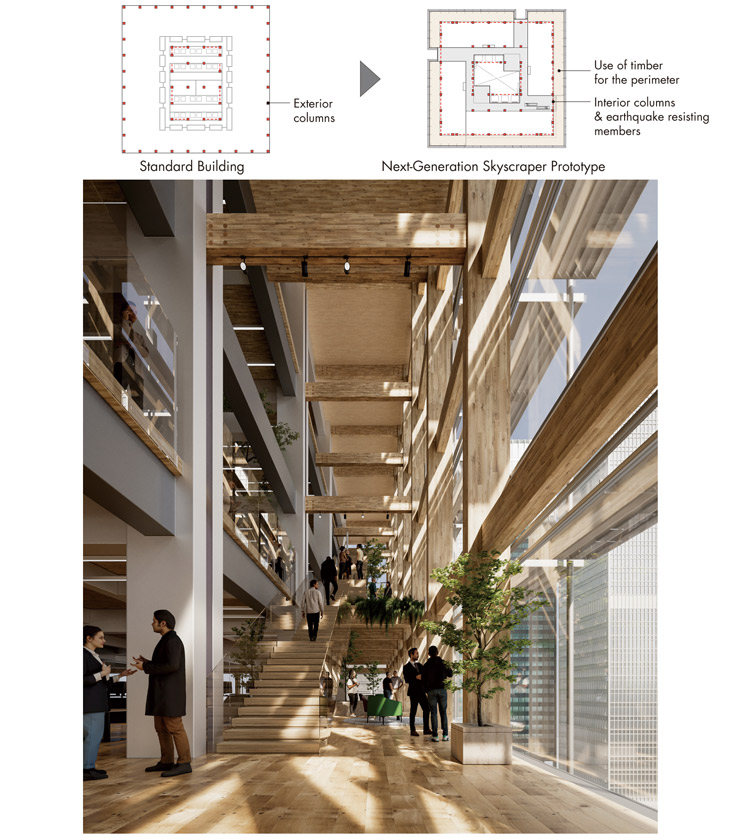

3. Planning for diverse work styles

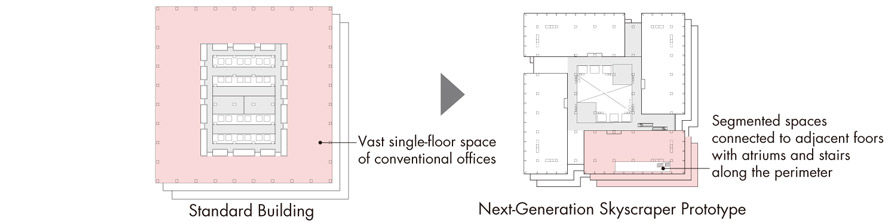

Connecting floors with atriums to promote communication

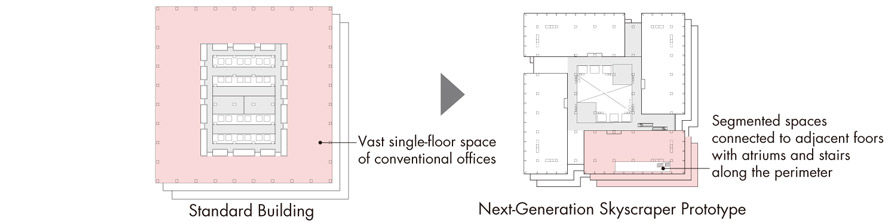

The floor plan is characterized by “stepped floors,” workspaces segmented by slits and connected with the upper and lower floors by atriums and stairs. Compared to the vast single-floor spaces of conventional offices, this design incorporates natural elements and brings employees closer together, promoting communication. By using wood flooring (CLT*5), the placement of atriums and stairs within rentable areas can be facilitated, and the overall building weight is reduced, leading to less steel and concrete usage and lower CO2 emissions during construction. This also contributes to CO2 reduction during the building’s operation phase by making refurbishments easier.

Figure 5. Stepped floors

Figure 5. Stepped floors

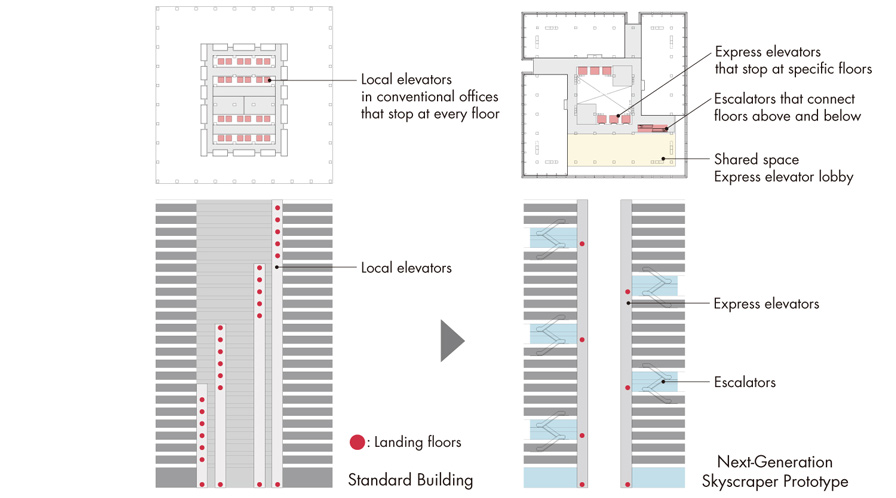

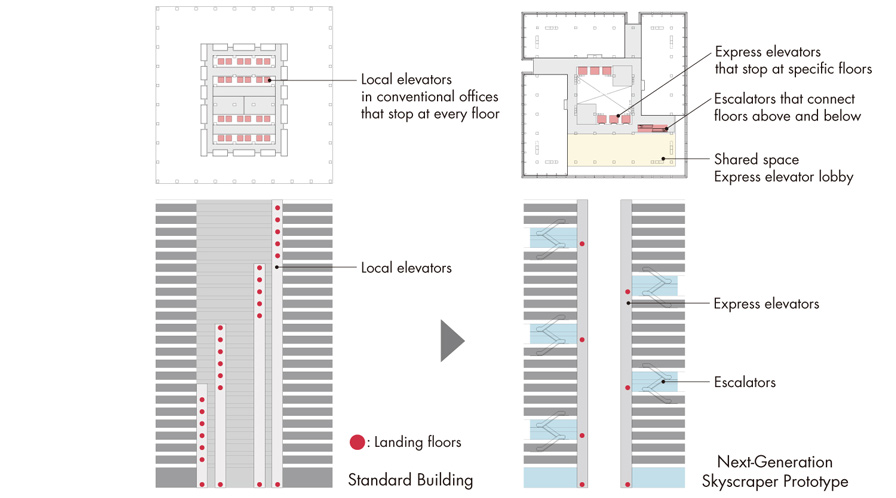

Switching to express elevators and escalators

Conventional skyscrapers contain enough local elevators, elevators that stop at every floor, to transport workers during peak times. However, as work styles change, office attendance tends to decline. Therefore, we have fundamentally re-evaluated this transportation system, replacing the local elevators with a combination of express elevators and escalators. Express elevators, suitable for long-distance transport, stop at specific floors, and the escalators, ideal for mass transport, connect floors above and below, thus maintaining transportation capacity while significantly reducing power consumption (5,650 kWh/day ⇒ 1,750 kWh/day*6).

Figure 6. Elevator plan

Figure 6. Elevator plan

*5 Abbreviation for Cross Laminated Timber. A wooden structural material made by layering and bonding sheets of wood with their grain directions perpendicular to each other.

*6 Comparison of daily power consumption between 24 local elevators and 6 shuttle elevators combined with 44 escalators.

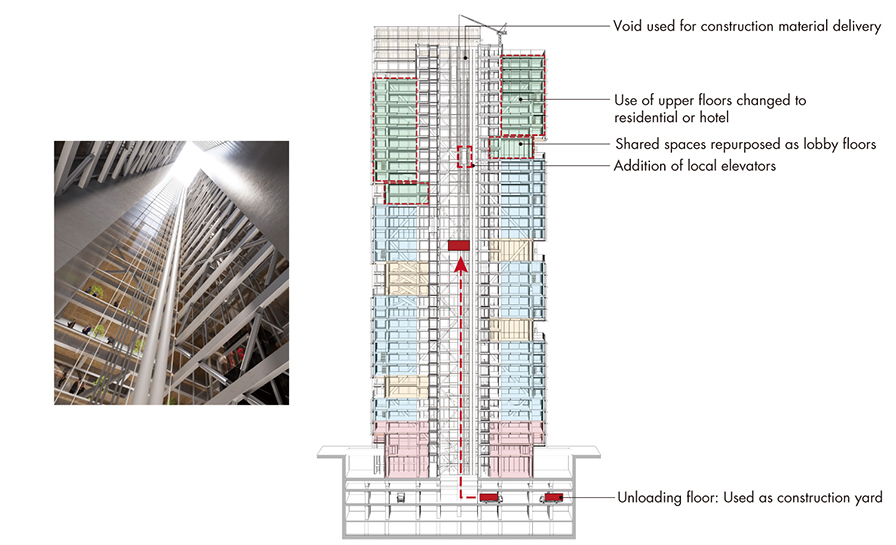

By removing the local elevators, a large void (atrium) is created in the center of the building. This void can contain the main utility lines to improve office space efficiency and serve as a natural ventilation path. It also makes maintenance, equipment replacements, and refurbishments easier, thereby reducing CO2 emissions during operation and contributing to sustaining the building’s value and longevity according to the needs of the times.

Figure 7. Utilization of the void

Figure 7. Utilization of the void

Providing diverse workspaces with shared spaces

Shared spaces, connected by escalators, are placed throughout the building in a spiral pattern to the rooftop. These spaces can serve as express elevator lobbies, can be combined with terraces and used as common refreshment areas, and include a variety of office support functions such as meeting rooms, cafes, bookstores, and coworking spaces. Building users can choose their preferred work environment among a diverse array of workspaces.

Figure 8. Shared spaces

Figure 8. Shared spaces

Many elements of this prototype can be applied not only to the construction of new large-scale buildings but also to the renovation of small and medium-sized buildings, which make up the majority of existing stock. Some elements, however, fall outside the scope of current evaluation systems or involve technologies still under development. Moving forward, we aim to implement the components of this prototype in individual projects through co-creation with our clients. We also intend to utilize this prototype to advocate for regulatory improvements and to continuously update its contents in response to technological advancements.

Nikken Sekkei’s “Climate Emergency Declaration*7”

In March 2021, Nikken Sekkei issued a “Climate Emergency Declaration” to realize a carbon-neutral society by 2050. We plan to propose models to achieve carbon neutrality in terms of work styles and urban/architectural design, and simultaneously share them with our clients and society to encourage all to join these efforts.

Nikken Sekkei’s company-wide design strategy “Nikken Design Goals (NDG)”

In January 2021, in response to organizational expansion and the increase in remote work, Nikken Sekkei formulated its first company-wide design strategy. From the best practices of each goal, we began researching prototypes to demonstrate universal design solutions to social issues. This prototype is the first under “Category 1: Designs to protect the global environment.”

Image collection of the next-generation skyscraper prototype

Figure 1. Overall image of the next-generation skyscraper prototype

Figure 1. Overall image of the next-generation skyscraper prototype

Figure 2. Overview of whole life carbon reduction measures used in the next-generation skyscraper prototype

Figure 2. Overview of whole life carbon reduction measures used in the next-generation skyscraper prototype Figure 3. Timber perimeter

Figure 3. Timber perimeter Figure 4. Environmental planning inspired by phyllotaxis

Figure 4. Environmental planning inspired by phyllotaxis Figure 5. Stepped floors

Figure 5. Stepped floors

Figure 6. Elevator plan

Figure 6. Elevator plan Figure 7. Utilization of the void

Figure 7. Utilization of the void

Figure 8. Shared spaces

Figure 8. Shared spaces