Nikken Sekkei has the most extensive resume of experience in Japan on the structural design of high-rise buildings, such as TOKYO SKYTREE℠, and is applying the knowledge, technology and expertise it has developed domestically over the years to design projects overseas. With One Za’abeel, Nikken Sekkei has challenged themselves to construct a new type of high-rise building, unlike any in the world, that structurally and functionally connects two 300-m high skyscrapers into a single structure by means of a linked bridge, aptly named THE LINK, located at a height of about 100 meters above an elevated expressway. A highly challenging structural design and construction plan was crucial for turning the concept put forward in the 2014 design proposal into reality, and we were able to solve issues through a combination of ingenuity in design and construction. When completed, One Za’abeel will be the tallest skyscraper ever designed anywhere in Japan or overseas with the involvement of architects from Japan.

Design Proposal & Concept

The 2014 design proposal received high marks for the value it added to the world’s longest cantilever linked bridge and iconic design.

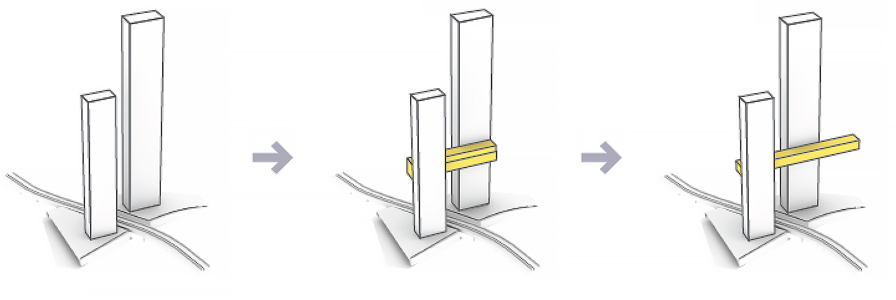

Two skyscrapers on a segmented site:

The construction of standalone skyscrapers on a site divided by an expressway raises issues in function and effective operation.

Value added with THE LINK:

The proposal included a design that would connect the two skyscrapers above the elevated expressway to provide added value, including more efficient operation of facilities, improved functions and an aerially-suspended event space.

Structural expression of an iconic masterpiece:

Nikken Sekkei proposed the design of an iconic skyscraper that combines the application and structural design of the world’s longest cantilevered building.

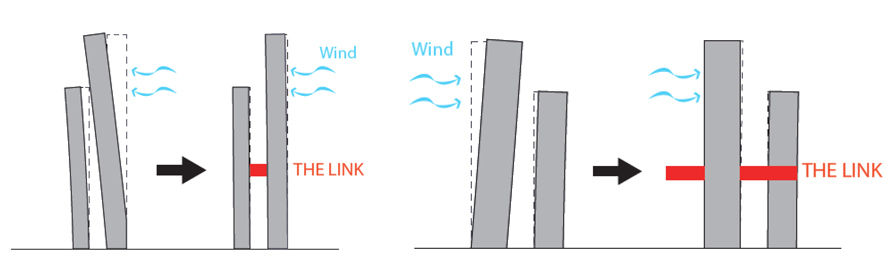

Structural system to enhance performance:

In designing a 300-m tall skyscraper, structural design becomes an issue to counter swaying in strong winds. We proposed to connect the two skyscrapers with a linked bridge to effectively control swaying in strong winds.

Ingenuity and Challenges in Solving Structural Design Issues

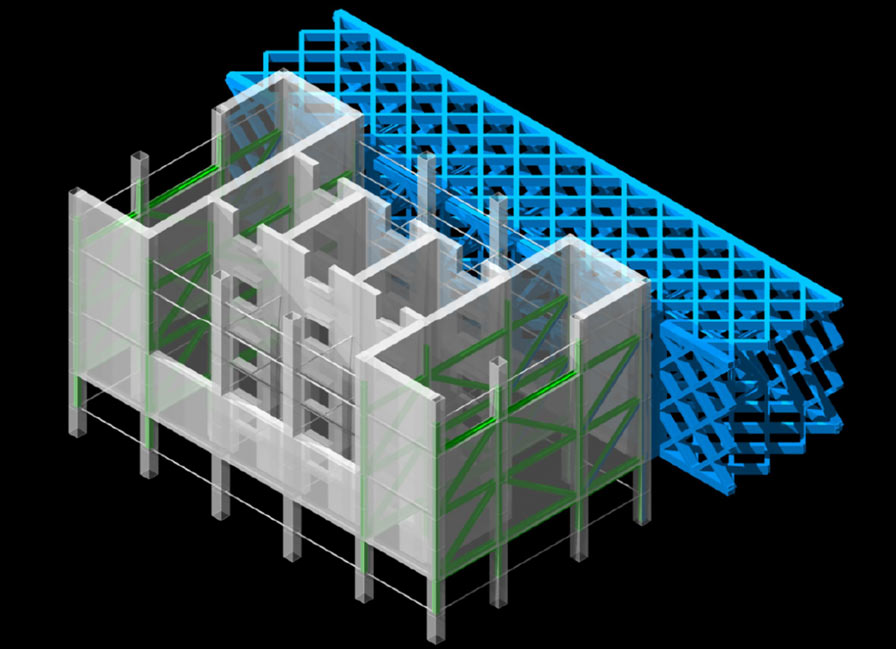

Adoption of a composite structure of concrete and steel

Generally, skyscrapers in Dubai are designed with a structural system that mainly uses inexpensive concrete. Compared with skyscrapers in Japan that are mostly designed using steel structures, column sizes are significantly larger, which reduces the floor space that can be used effectively. When designing the structure, we applied Japan’s expertise in structural design and adopted a cost-effective composite structural design with the placement of steel frames inside concrete columns to reduce the size of the columns by 30% to 50% and increase available floor space. To safely support THE LINK, a composite structure was used to strengthen the connection points to the towers with the placement of high-strength steel braces (green) inside concrete walls (white).

Diamond-grid structure of THE LINK and column-free spaces

THE LINK, which is the longest cantilevered building in the world at more than 60 meters, is not in alignment with the axis of the towers, and therefore, cannot avoid twisting and flexing under its own weight. Therefore, we proposed a design featuring a structural system with a rigid outer shell where the main steel braces are arranged in a diamond-like grid along the four outer surfaces of THE LINK to reduce flexure and torsional deflection. This also serves as a design element creating a large, column-free space on THE LINK that allows it to be efficiently used as an event space.

Safety in strong winds and livability guaranteed

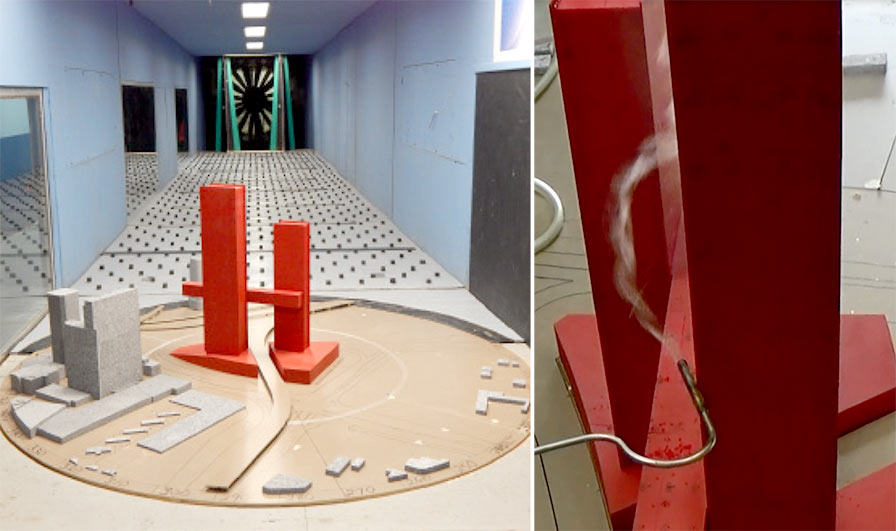

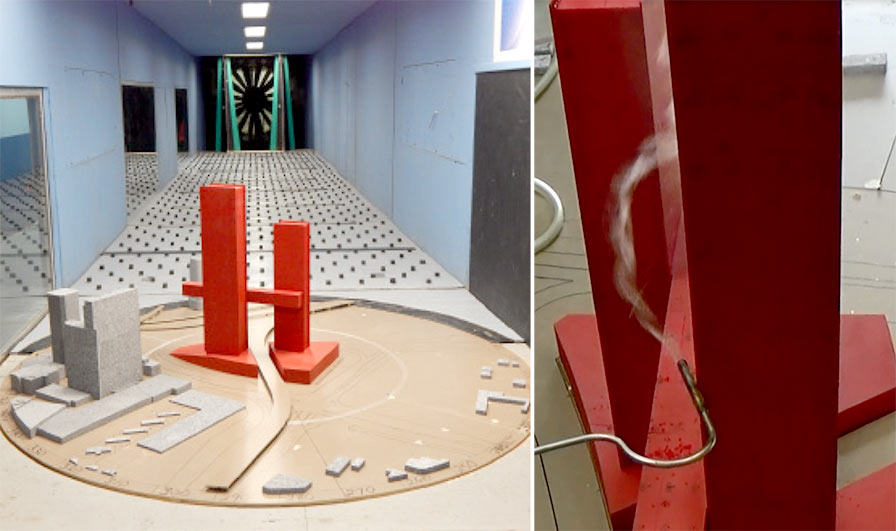

Although earthquake-resistant design is generally an important aspect for architecture in Japan, guaranteeing safety in strong winds and ensuring livability were important issues in the design of this 300-m class high skyscraper. Nikken Sekkei collaborated with RWDI, international consultants that also conducted wind load evaluations for Burj Khalifa, the tallest structure in the world, in conducting a wind tunnel test to evaluate the complex wind conditions around the two buildings located in close proximity to one another and THE LINK. Wind loads were set to gain insight into the complex behavior of the buildings in high winds, as well as the wind environment in the rooftop pool on THE LINK and low-rise areas to counteract the effects of high winds.

Photo Credit by RWDI

Photo Credit by RWDI

Complex behavior of buildings in high winds

Ingenuity and Challenges in Solving Construction Issues

Special construction processes and ingenuity were used to safely install the 230 meters long linked bridge at a height of about 100 meters above the elevated expressway.

Sliding method used in the assembly of THE LINK

Each steel brace for THE LINK was produced in factories and assembled on site after the delivery of eight blocks ranging in length from approximately 20 to 30 meters. In order to minimize the work on the elevated expressway and increase safety during construction, we completed the assembly of THE LINK by challenging ourselves with a special construction method in which precast blocks are slid one after the other and joined together in succession over seven times to clear the 40-meter wide highway.

On-site assembly of massive blocks for THE LINK

On-site assembly of massive blocks for THE LINK

Third step in the sliding process (October 2019)

Third step in the sliding process (October 2019)

Fourth step in the sliding process (November 2019)

Fourth step in the sliding process (November 2019)

Fifth step in the sliding process (December 2019)

Fifth step in the sliding process (December 2019)

Lift-up method to install THE LINK

THE LINK, which weighs about 9,580 tons and is 230 meters long, is a massive single block that will be lifted up and attached to the two towers. The tip of the cantilever will be installed in position after the second lift up.

Lead Consultants & Leadership

As the lead consultant, Nikken Sekkei coordinates with a number of consultants overseas and is responsible for the design of the project and supervising the construction process. With engineers from more than 20 countries involved in the design and construction of THE LINK, Nikken Sekkei is taking leadership as it plays the role of lead consultant with the goal of achieving one of the world’s most challenging design and construction projects.

Photo Credit by RWDI

Photo Credit by RWDI

On-site assembly of massive blocks for THE LINK

On-site assembly of massive blocks for THE LINK

Third step in the sliding process (October 2019)

Third step in the sliding process (October 2019)

Fourth step in the sliding process (November 2019)

Fourth step in the sliding process (November 2019)

Fifth step in the sliding process (December 2019)

Fifth step in the sliding process (December 2019)